SUNNYBROOK WELDING BLOG

The Future of Manufacturing: 2024 and Beyond (The Involvement of AI)

AI injects a new level of intelligence and adaptability into manufacturing

As we step into 2024 and beyond, the manufacturing landscape is undergoing a profound transformation, driven largely by advancements in artificial intelligence (AI). For welding and machine shops, this shift is not just a glimpse into the future but an immediate, game-changing reality.

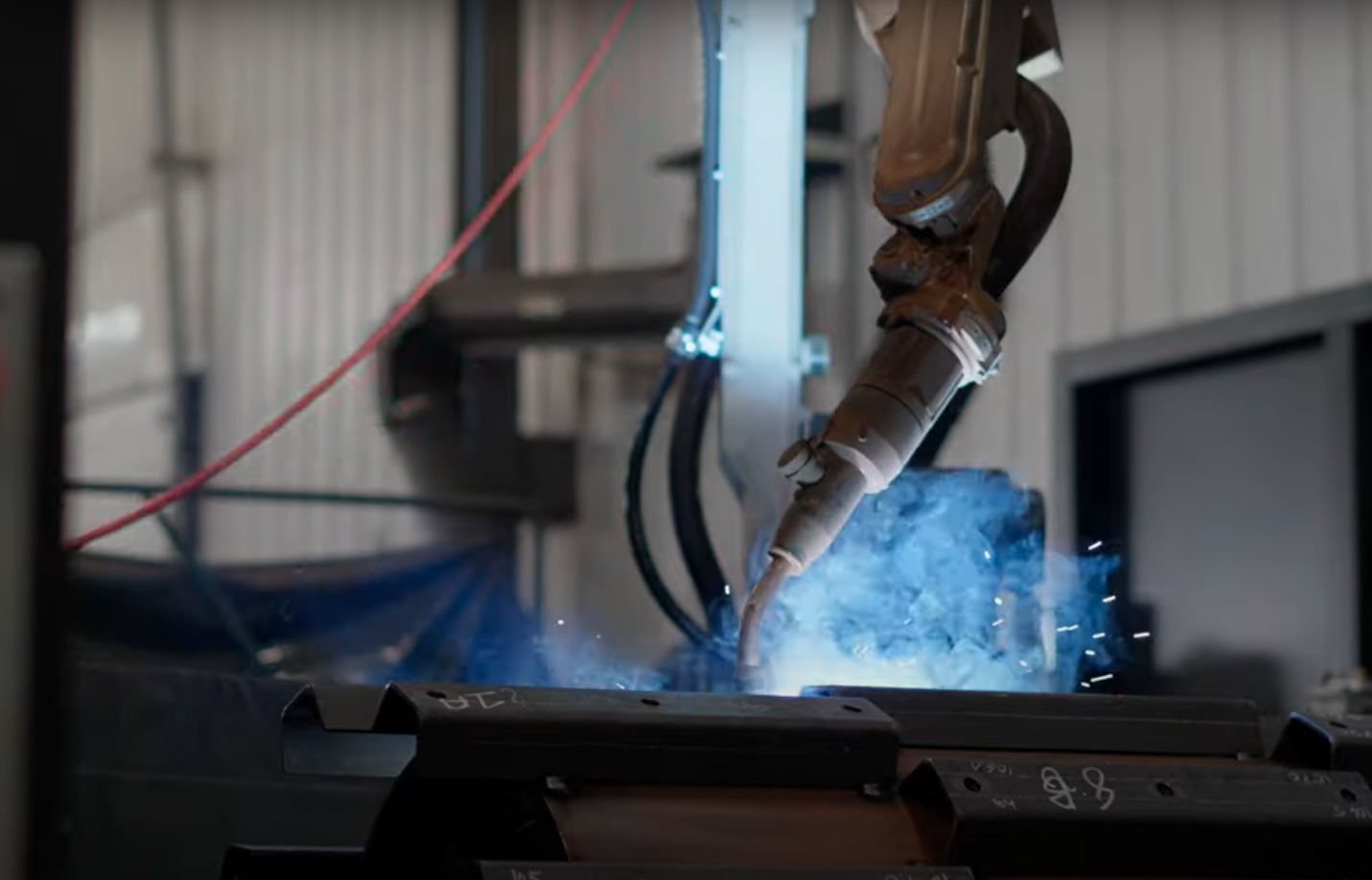

In a rapidly evolving manufacturing landscape, AI-driven innovations are revolutionizing welding and fabrication processes. These advancements enhance precision and efficiency and fundamentally transform how tasks are executed in these industries. From automated welding systems that ensure consistent quality to predictive maintenance that minimizes downtime, AI injects a new level of intelligence and adaptability into welding and fabrication shops. As we embrace this technological leap, the fusion of AI with traditional manufacturing techniques, are paving the way for unprecedented levels of productivity, customization and innovation.

1. Precision and Efficiency through Automation:

Precision is paramount in welding and machining. AI-powered automation can perform complex welding and machining tasks with unparalleled accuracy. Advanced sensors and real-time data analysis enable machines to adjust parameters on the fly, ensuring consistently high-quality outputs with minimal human intervention. This automation reduces waste and significantly increases productivity.

2. Predictive Maintenance:

AI systems excel at predicting when machinery is likely to fail, allowing for pre-emptive maintenance. By analyzing data from sensors embedded in welding and machining equipment, AI can forecast potential breakdowns before they occur. This predictive capability minimizes downtime and prolongs the lifespan of expensive machinery, ultimately saving shops considerable time and money.

3. Enhanced Quality Control:

AI-powered quality control systems are revolutionizing the way we ensure product quality. By leveraging machine learning algorithms, these systems can identify defects that may escape the human eye. In the field of welding, for instance, AI can analyze the quality of welds in real time, promptly detecting cracks or weak spots. This immediate feedback loop ensures that any deviations from quality standards are swiftly rectified, reducing the risk of defective products reaching the end customer. This is just one example of how AI is reshaping quality control, promising improved product quality and customer satisfaction.

4. Design and Simulation:

AI is also transforming the design phase of manufacturing. Advanced AI software can simulate welding and machining processes, predicting outcomes and optimizing designs for manufacturability. This capability allows developers to experiment with different approaches in a virtual environment, leading to innovative solutions and faster time-to-market for new products.

5. Customization and Flexibility:

With AI, welding and machining shops can handle customized orders more efficiently. AI systems can quickly adjust to new specifications without extensive reprogramming. This flexibility is crucial in today's market, where customer demands are increasingly diverse and personalized.

Real-World Applications and Future Trends

Case Study: AI in a Modern Welding Shop

Consider a welding shop that has integrated AI into its operations. Robots equipped with AI algorithms handle repetitive and hazardous welding tasks, ensuring uniformity and safety. Meanwhile, human welders focus on more complex and creative aspects of projects, supported by AI tools that provide real-time data and insights. This synergy between human expertise and AI enhances overall productivity and job satisfaction.

Case Study: AI in a Machining Shop

In a machining shop, AI-driven CNC (Computer Numerical Control) machines use machine learning to optimize cutting paths and tool usage. These machines learn from each operation, continuously improving efficiency and reducing material waste. AI-powered software analyzes each completed part, ensuring it meets exact specifications and immediately flagging any discrepancies for review.

Future Trends to Watch:

Collaborative Robots (Cobots): These robots are designed to work alongside humans, combining the precision of AI with the creativity and problem-solving skills of human workers. Cobots can handle mundane tasks, freeing up human operators to focus on more intricate aspects of welding and machining.

AI-Powered Supply Chain Management: AI will be critical in optimizing supply chains, predicting demand, managing inventory, and reducing lead times. For welding and machining shops, this means more reliable access to raw materials and quicker turnaround times for customers.

Sustainability: AI will help shops become more sustainable by optimizing energy usage and reducing waste. Smart energy management systems can adjust power consumption based on real-time needs, significantly lowering the carbon footprint of manufacturing operations.

Conclusion

Integrating AI into welding and machining is not just a trend; it's a new reality. As we look beyond 2024, the role of AI will only become more pronounced, driving innovation, efficiency, and sustainability in manufacturing. Shops that embrace these technologies today will be the leaders of tomorrow, setting new standards in quality, productivity, and customer satisfaction.

For welding and machining shops, the future is bright, and it's powered by AI. The journey is just beginning, and those who adapt will thrive in this exciting new manufacturing era.